Gaggiuino and Topology Optimization

I wanted to commemorate the completion of my undergraduate career with a ring similar to iron rings historically awarded to some engineering graduates - but with my own personal twist. As I was concurrently taking a SolidWorks course, this doubled as a great method to assess my skill level in the software at the time. All designing was completed on my own in SolidWorks before distributing the file to Shapeways for their printing and casting services.

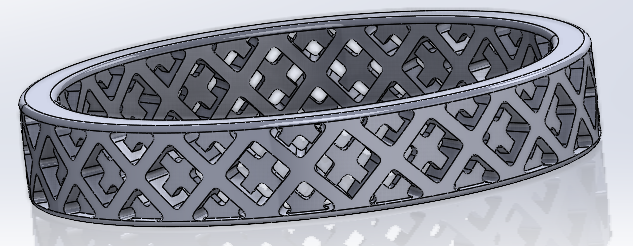

The base geometry was inspired by common, simple rings and sized according to the measurements of my pointer finger. I wanted to incorporate complex geometry into the details that would be difficult to manufacture through traditional subtractive means. I decided on the criss-cross design (as seen in the photo.) The design began with a ring of an appropriate size. Next, the mirrored triangle pattern was created and wrapped once around the base geometry; I then duplicated this layer and placed this new one on the main one then rotated it so the main diamond had an x through it. Thus creating the geometry. All I had to do then was add the fillets to make the ring nicer to put on and aided in the design. I then sent it off to Shapeways to get printed. I chose silver as the material as I wanted something more precious than steel or bronze but not too expensive like gold, and surprisingly silver wasn't very expensive(in 2021).