Additive Manufacturing

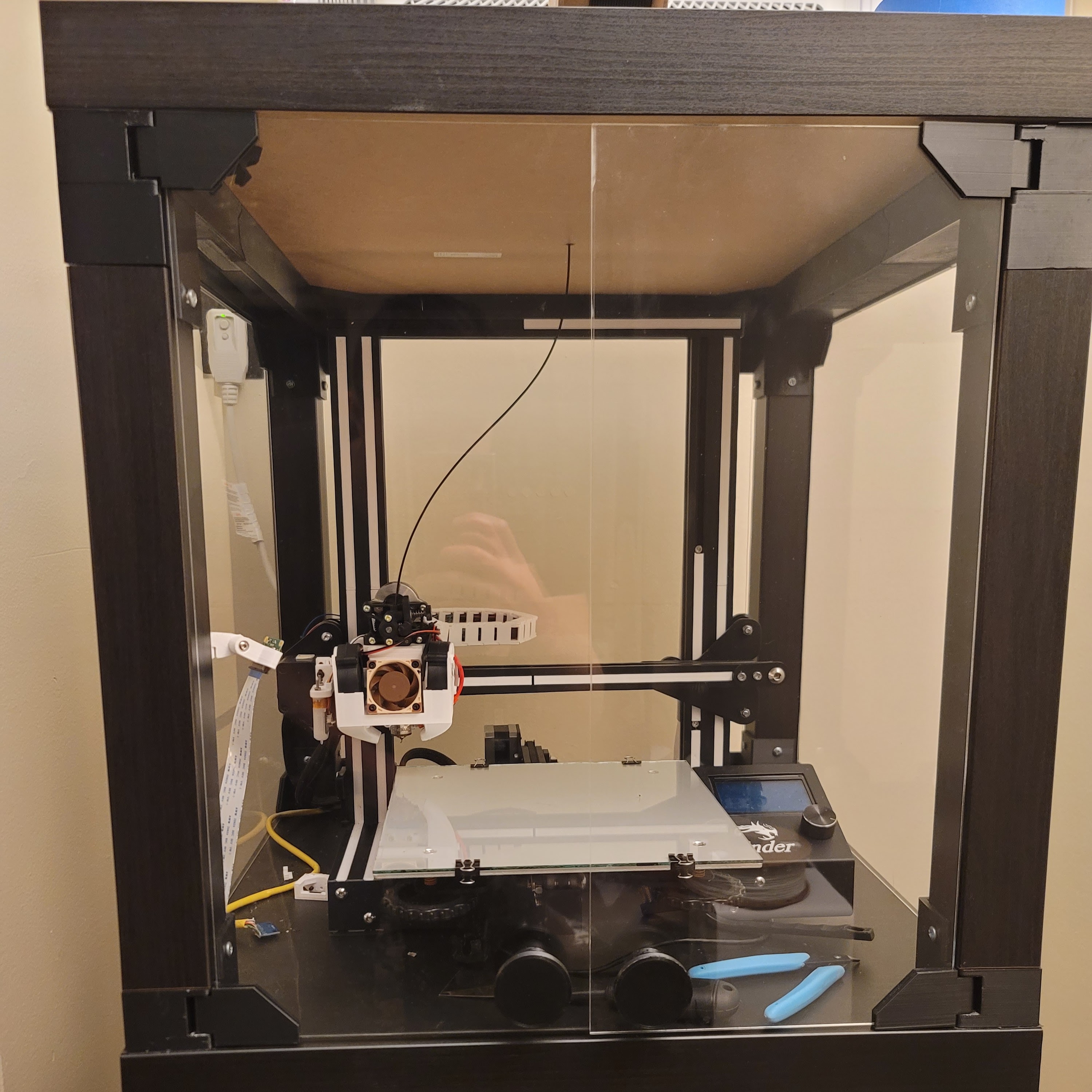

I have extensive experience in fused deposition modeling (FDM) printing through my personal Ender 3 that I have extensively modified.

I have extensive experience in fused deposition modeling (FDM) printing through my personal Ender 3 that I have extensively modified.

I am a Certified SolidWorks Associate and am experienced in other CAD softwares (NX, AutoDesk Inventor, Onshape, and Fusion 360).

I am proficient in various programming lanugages: MATLAB, C++, HTML, XML, and Java.

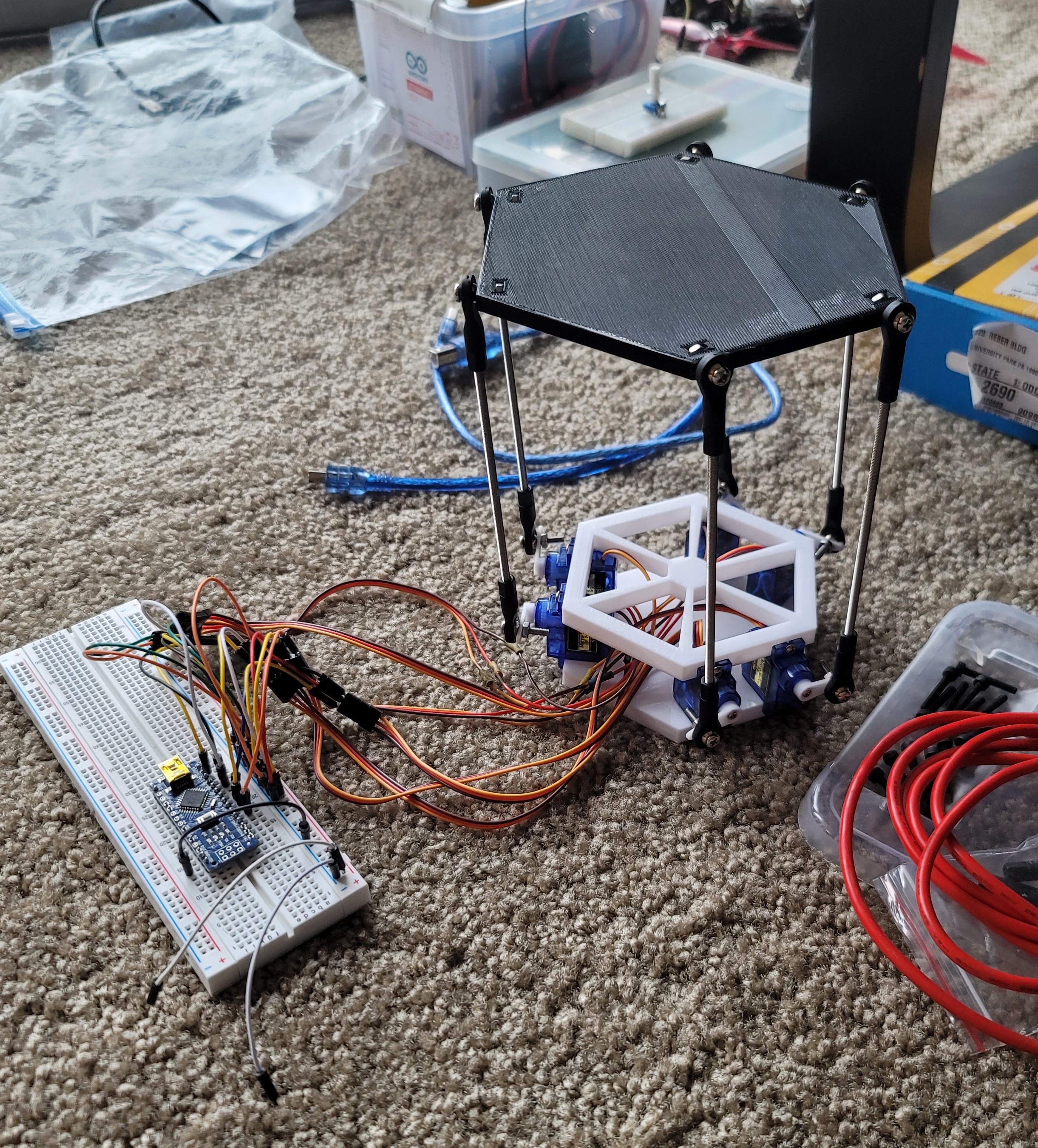

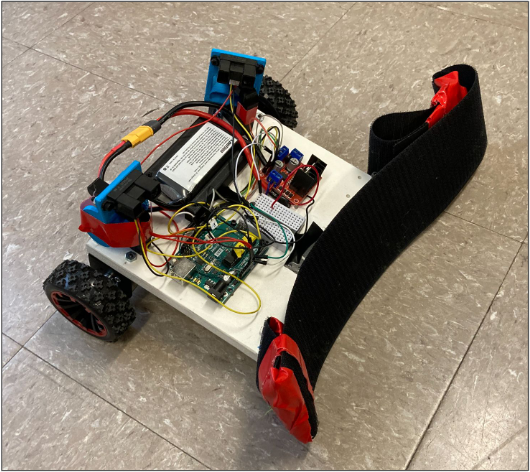

I have abundant experience using arduinos in many of my personal projects and thesis research, as well as through assistant teaching for the undergraduate mechatronics class at Penn State for 2 years.

Desktop microphone for personal use total cost ~$30

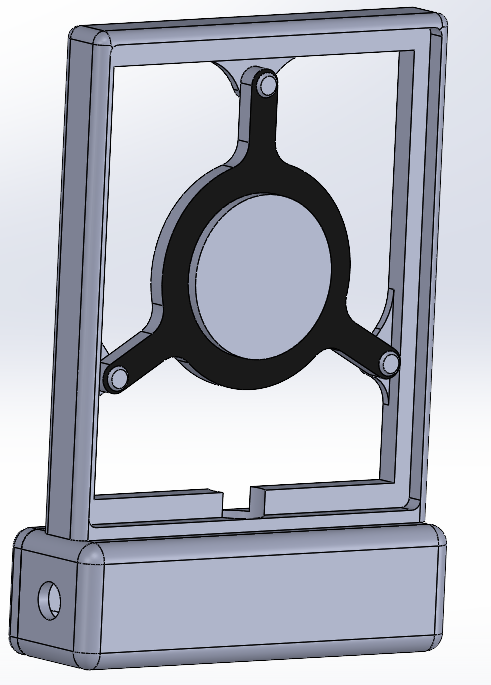

A mechanism I designed for a take home challange.

My master's thesis titled "A Unified Method to Calculate Safety Surrogates for an Autonomous Vehicle in Work Zones."

Modified my Espresso machine to allow proportional-integral-derivative (PID) control for the boiler and pressure control for shot-pulling. Made topology optimized towel rack brackets.

Heavily modified my Ender 3 to allow for cleaner and more efficient printing.

Interest in learning how to make forged carbon fiber parts led me to make a shift knob for my car as a foray into the topic.

Main hands-on research project for summer of 2022.

Final project for ME 581 - Simulation of Multibody Dynamics.

Final project for ME 545 - Graduate Mechatronics.

Final project for ME 556 - Robotic Concepts.

Wanted to test my 3d modeling skills and develop a fun deliverable in the process.

Final project for ME 340 - Mechnical Engineering Design Methodology.

Autodidactic learning about drones and first person view (FPV) technology.

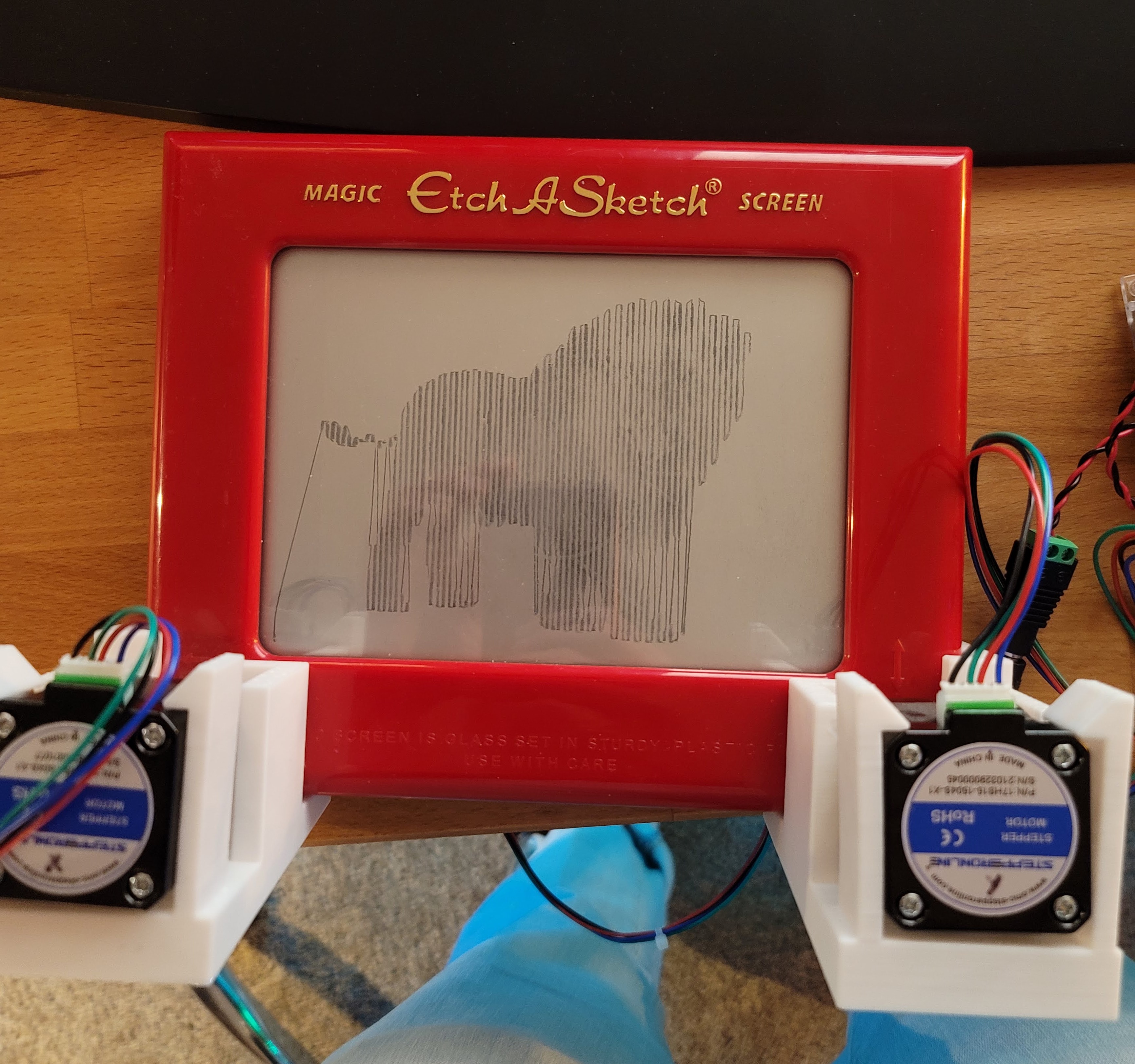

One of my first personal mechatronics projects.